jueves, 21 de enero de 2010

Aluminum Foundry Timeline

Etiquetas:

alloy,

aluminum,

development,

dipity,

foundry,

manufacturer,

products,

technology,

timeline

sand cores

This are some pictures of shell cores for aluminum casting that we found on the web, what do you think of this process? Do you use it? is it different?

Leave us a comment with a link to your page, we will be glad to know from you!

viernes, 15 de enero de 2010

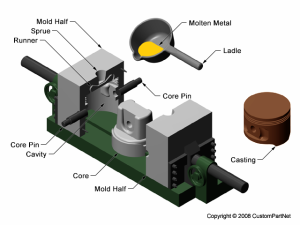

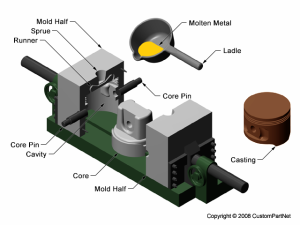

Permanent mold castings is a process that is commonly used to produce aluminum, magnesium and copper products and parts, in difference with the sand casting process, this one employs metal reusable molds.

This process is great for producing big scale production highly precise castings with good surface finishes, when used for aluminum alloy castings the permanent molds, with their proper maintenance, can be very durable and profitable.

This process is great for producing big scale production highly precise castings with good surface finishes, when used for aluminum alloy castings the permanent molds, with their proper maintenance, can be very durable and profitable.

lunes, 11 de enero de 2010

aluminum alloys

Aluminum alloys are formed commonly with copper, zinc, manganese, silicon and magnesium as the alloying elements. This components help to give aluminum better properties, such as cost effectiveness due to the melting point.

There are many kinds of aluminum allow compositions, you can find a general description of aluminum alloys in the matweb, you can find also some data about most used aluminum alloys in casting here.

Aluminum alloys are ideal for manufacturing a recyclable, light and stiff product, it is also very diverse in the forms that it can take thanks to processes as sand casting and permanent mold casting (described in previous posts) among other processes.

(via aluminum foundry's blog )

viernes, 8 de enero de 2010

Aluminum Castings

Aluminum castings can be made with many different techniques that work for different purposes. For a low to middle sized production the most recommendable in order to have competitive costs while maintaining a high quality will be to use sand casting or a permanent mold casting.

Sand aluminum castings are ideal for a low production, it allows a quick manufacture maintaining a low budget, it also offers the possibility of having a versatility in the production process since it would be relatively easy to make a change on the printing model.

Permanent mold castings are much better for a middle range production, it offers a higher fidelity on the aluminum product or part and it is also much faster to manufacture than other methods, with this kind of casting you will get high quality and control over your aluminum products.

If you are interested in quoting aluminum castings you can go to our aluminum castings parter page.

Sand aluminum castings are ideal for a low production, it allows a quick manufacture maintaining a low budget, it also offers the possibility of having a versatility in the production process since it would be relatively easy to make a change on the printing model.

Permanent mold castings are much better for a middle range production, it offers a higher fidelity on the aluminum product or part and it is also much faster to manufacture than other methods, with this kind of casting you will get high quality and control over your aluminum products.

If you are interested in quoting aluminum castings you can go to our aluminum castings parter page.

(via Aluminum Foundry's Blog)

Suscribirse a:

Entradas (Atom)